How our nano-architecture enhances a pyrolysis process

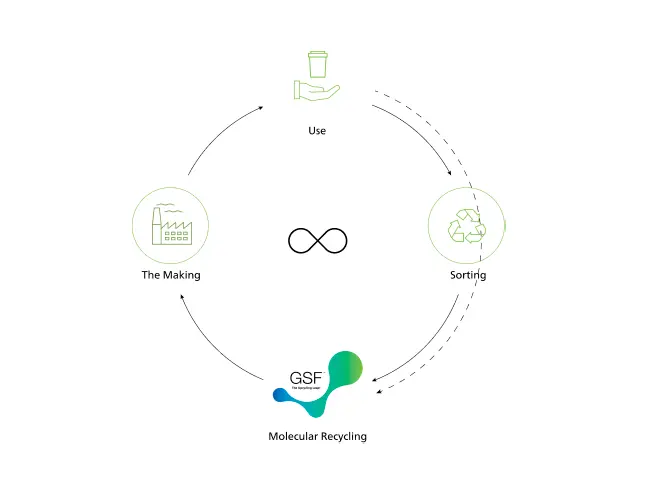

We breakdown polymers into their base building blocks, monomers, and add what is “missing” to the mix to create sustainable high value products from mixed plastic waste.

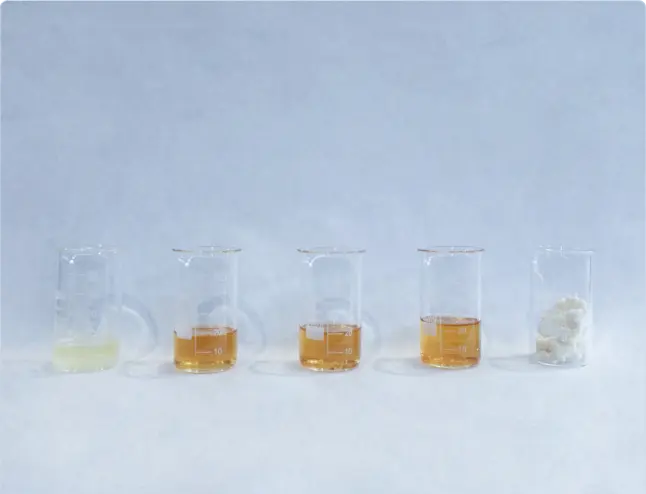

The structure of the carbon-based nano-materials allow carbon atoms to decouple in a gradual and continuous way, forming new compounds.

We base our technology on the homogeneous affinity between carbon-carbon chains in mixed plastic waste and our reagents.

It allows us to remove certain pollutants, such as Halogens, Metals, Heteroatoms and reduce or avoid Coke Formation.

A higher quality of py-oil that may enable superior performance in a steam cracking environment.